Plastic Is Fantastic however the Plastics Industry has a PR problem.

We all know Plastic is the optimum material for the majority of packaging applications from both an environmental and commercial point of view.

However, because conventional plastics is not degradable and flexible packaging is non-recyclable; pollution due to carelessly discarded post-consumer plastics waste is now a worldwide problem and the issue is what to do with the thousands of tons of plastic waste which cannot realistically be collected for recycling or other forms of responsible disposal, and escapes into the open environment, endangering wildlife and clogging up waterways?

It is now under constant attack from NGOs, pressure groups, governments and media organisations.

The biggest global issue is the abundance in the environment due to thoughtless disposal litter.

There is now a great deal of pressure on the plastics industry to become more 'Green'.

Types of Biodegradable Plastics

It should be clearly understood that there are two very different types of biodegradable plastic.

-

Compostable (also loosely known as "bio-based plastics" or "bioplastics") and designed according to EN13432 to biodegrade in the special conditions found in industrial composting and will not biodegrade in the open environment,

-

Biodegradable made from petroleum-derived polymers such as PE, PP and PET, containing active ingredients (which do not include "heavy-metals") designed according to ASTM D6954 to degrade and biodegrade in the open environment leaving no harmful residues. (Oxo-degradation is defined by CEN in TR15351 as "degradation resulting from oxidative cleavage of macromolecules." And Biodegradable as "degradation resulting from oxidative and cell-mediated phenomena, either simultaneously or successively.")

What We Offer

Reverte Biodegradable Additives Masterbatch

If we are concerned about litter in the environment there is no point in choosing "compostable" plastics which obviously have to be collected before they can be composted. By contrast, biodegradable plastics can be re-used and recycled during their useful life, and only if they do not get collected will they ultimately biodegrade in the open environment by a two stage process; (a) oxidative degradation, which is chain scission in presence of heat and sunlight, followed by (b) biodegradation.

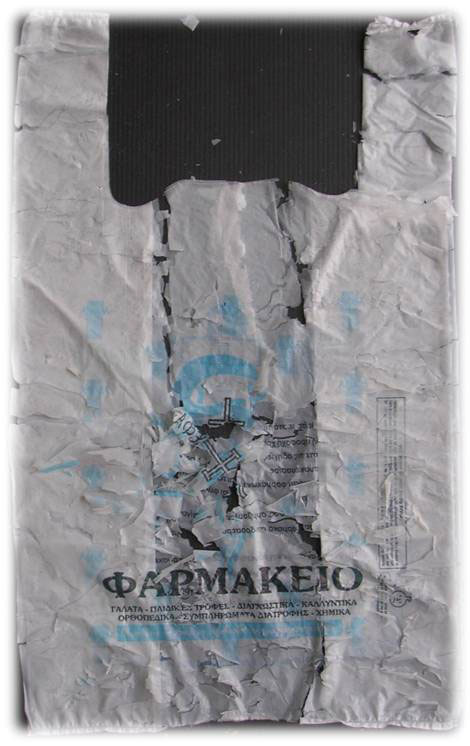

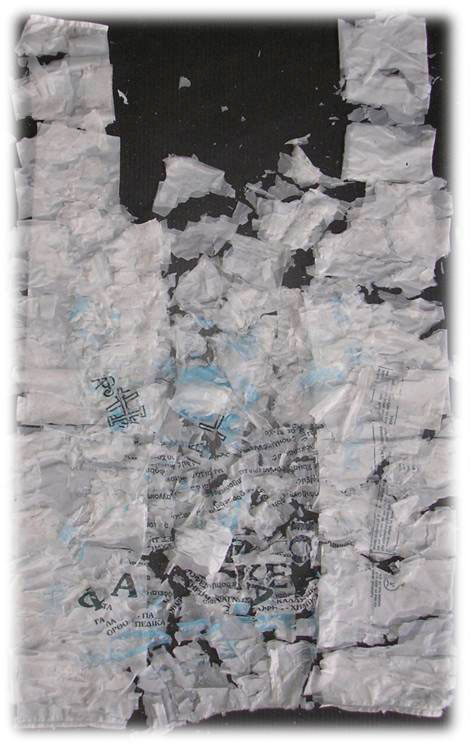

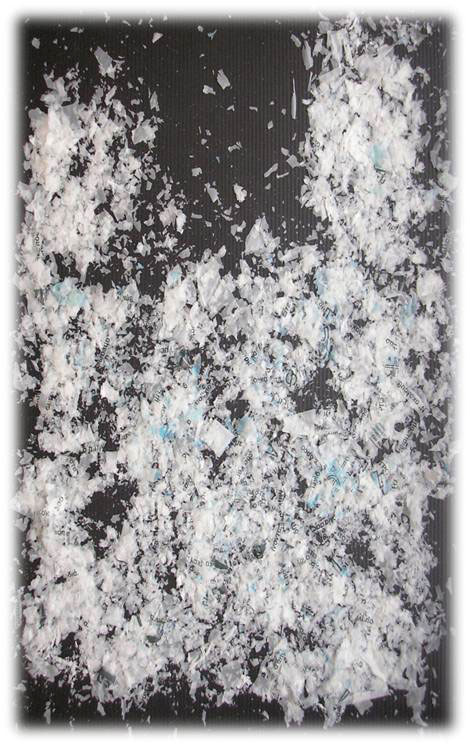

What is Reverte

Reverte is a family of Biodegradable additive masterbatches which has been developed for a wide range of polymers and packaging applications. The term 'Oxo-biodegradability' is a hybridisation of two words; oxidation and biodegradability. It defines clearly a two step process initiated in this case by the Reverte additive degrading (breaking up) the polymer chain in order to make it available for biodegradability within the environment when a treated item has finished its useful life. The oxidation phase reduces the polymer molecular weight and introduces oxygen into the structure. This process transforms the plastic from long strands to much smaller lengths. By reducing the chain length of the polymer the material loses its physical strength, making it brittle and non-plastic . The biodegradability aspect refers to the conversion of these lower molecular weight species by bacteria into biomass, CO2 and H2O.

Biodegradables

-

Help reduce the impact of plastic waste on the environment.

-

Adds value to products and brands.

-

Small addition (generally 1%) renders standard polyolefins Biodegradable .

-

No modification or investment in machinery required for manufacturers.

-

Cost effective method of enhancing the environmental credentials of plastics.

-

Allows all the performance aspects of your polymer blend to be maintained.

How It Works

Addition of 1% by weight in the polymer make ordinary plastics biodegradable.

Applications Area

BD 93470 - For PP films

BD 92771CC - For PE films

BD 94285 - For PET films and Laminates